Development competencies

Our SCS development team carefully weights opportunities and risks of each new idea. This results in products that are optimally tailored to your use case—innovative, with the highest quality standards and cost-efficient production. What each product development focuses on: you and your product.

We have made a name for ourselves as a competent development and value-add partner. Renowned automotive manufacturers have been counting on our competency—often for many years. With excellent processes and products, we jointly devise market achievements. We are at our customer’s side through the entire development and manufacturing stages—from design and prototype construction to series manufacturing.

We include you in the development stage for new vehicle models. As your strategic supplier we will assume component design and testing responsibility at an early stage. In addition, we devise solutions for you for friction optimization. Cross-site CAD, production planning and control systems support our continuous development process and you will benefit right from the start from efficiency in approvals and production.

We will develop concepts for Bowden cables and Bowden cable systems for you, including actuation and transfer systems such as grip units, force transfer components and coupling boxes.

Together with you we will carefully choose the materials for your product. This results in SCS components and assemblies precisely fitting in with your custom specifications.

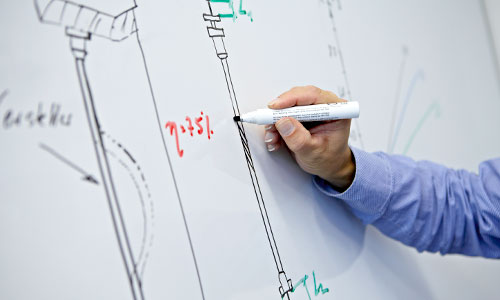

Before we manufacture your future product, we will use models to check its function, design and feature set. So we can be sure that it will work excellently.

Based on these functional models we will detail the draft designs for your future product. At this stage of product development we will create precise needs-based drawings.

We conduct meticulous test series for you to always guarantee you an optimum product quality. We test all of our Bowden cable systems on in-house test benches.

Manufacturing competencies

Systematic. Innovative. Moving.

SCS is a multinational company with modern quality-assured manufacturing and process structures. These professional structures at our production sites make us a widely recognized value-add partner: Our automotive and industry customers alike appreciate our excellent manufacturing competencies. And trust the reliable results of our everyday work: Products meeting the highest international quality standards.

What is the basis of our manufacturing success and collaborative partnering with our customers? A perfect balance of traditional craftsmanship and cutting-edge manufacturing approaches. Highly qualified specialists who always know exactly what they do. Modern machine fleets and automated assembly stations—for a highly efficient production of components and assemblies.

Our core manufacturing competencies at a glance:

Helical windings are the core components of a Bowden cable. At our German location we produce all the helical windings we need for series productions in Poland and Hungary. We manufacture the helical winding inner tube and the helical winding sheath in a plastic extrusion process. We use special winding machines to produce the metal core of our helical windings. Our manufacturing capacity in m is in the double-digit millions.

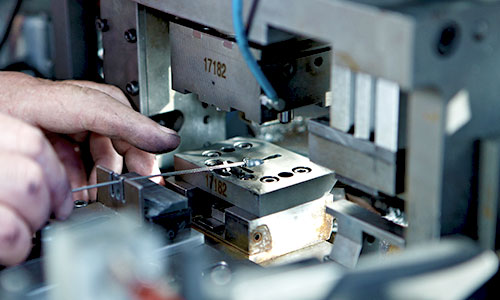

Each one of our Bowden cables has special end pieces for connecting the cable ends. This connection is made using either zinc die-casting hydroseeding or a loose part and a press method.

For metal processing we also offer you the option to precisely tailor our products to your individual needs.

We produce all the plastic components for our Bowden cables at our German site. Here, we also manufacture technical plastic items for vehicle interiors such as handles for unlocking the engine hood and seat linings. Our machine fleet comprises the latest technology by Arburg and Engel. The plastic components manufactured at our German plant are delivered to our series production plants in Poland and Hungary.

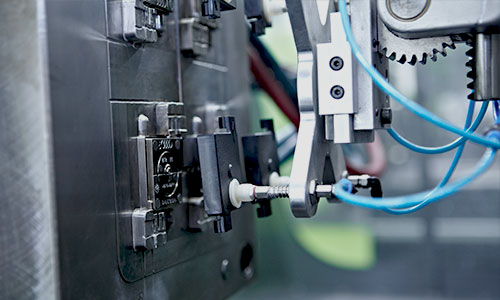

SCS plans, designs and produces the product-specific manufacturing fixtures, measuring equipment, test facilities and tools. At our German and Canadian sites we work with cutting-edge machine fleets—for excellent in-house fixture construction and tool making. This enables our highly qualified employees to realize even complex systems in the shortest of timeframes.

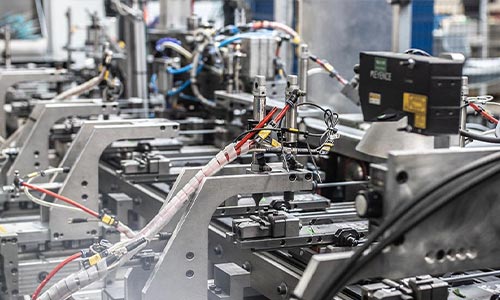

Our competent employees in China, Hungary and Poland use smart techniques to manufacture large-volume Bowden cable series. Whether produced in lines, groups or U-shapes. With every product, we keep a very precise eye on our automotive and industry customers’ enormously high quality standards.

Apart from traditional manual manufacturing processes needed for producing a lot of our Bowden cables, we also work intensely on automation solutions. For many years we have been successfully using sensible solutions—from semi-automated component manufacturing to fully automated “man-less” large series manufacturing.